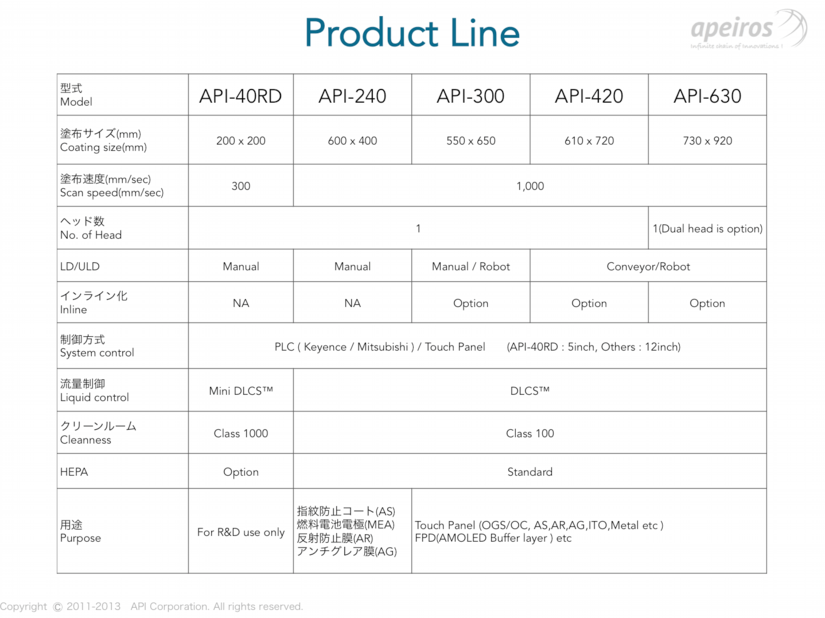

High Precision Spray Coater with DLCS™ serves many diverse fields and applications. Such as commercial R&D and laboratory level experiments. Specifically, this spray coater technology is required when conventional coating methods don’t work. For instance, major applications. Such as Touch panels (OGS/OC, AS, AR, AG, ITO, metal), next-generation renewable batteries (fuel cell and others), and medical and biochemical fields. Therefore, this technology is able to serve other unique and challenging applications.

Click on a Machine to learn more:

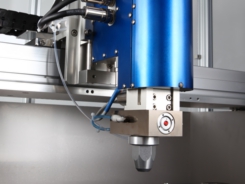

To clarify, the monolithic spray head creates a discharge accuracy of 0.1-1.0%. Due to the fact it uses its own flow control technology DLCS ™ (Digital Liquid Control System).

To emphasize, this machine is equipped with a two-fluid nozzle, a sub-tank, and degassing mechanism. For that reason, no pulsations occur.

As a result, no clogging occurs in either structure of the nozzle.

Specifically, our technology is based on years of spray coating process control. To operate you set the application parameters, the nozzle cleaning, bubble opener, and recoating parameters. Then monitor the application state.

Most importantly, you can operate the system controls on the 12” touch panel.

In addition, the temperature and humidity are controlled during the application operation. Lastly, the data is recorded, making it possible to give feedback to the production management.

The Standard Model API-240 is controlled with a touch panel. The touch panel allows control of the anti-fingerprint coatings, AG / AR coatings, and fuel cell electrode coating.

In addition, you can use the conventional coating processes (slit die, a roll coater, a spin coater). Therefore, resolving the respective unique challenges and adoption of mass production is expanding.

Spray Coating Solutions:

Due to the rapid market expansion our one glass solution for smartphones, tablet PC, touch panel market is exploding. Owing to our innovative technologies to produce thinner, stronger glass.

To demonstrate, the API-300OC uses the OGS (One Glass Solution). For this reason, OGS was developed as a membrane process for devices. Another key point is the excellent film thickness and uniformity when compared to conventional spray coating.

In conclusion, this will improve the yield at the time of mass production.

The API-40RD is equipped with a Mini DLCS ™. The API-40RD is a compact tabletop precision Spray coater ™. This machine uses a disposable syringe head. Therefore, it can be precisely applied with a minimum of 3cc chemical solution, Tegaeshi well.

The result is minimum use of material. The HEPA filter and adsorption stage is standard equipment.

Therefore, it is possible to uniformly apply the fine particles, 10-15μ by LPVN ™. The ejection accuracy rate is 1% of the flow rate. Making it scalable to the mass-production process.

Oleophobic anti-fingerprint coating has been used by Apple since the iPhone 3GS and other PC manufacturers. The anti-fingerprint is an oil-repellent coating technology. Conventionally, this has been deposited in an expensive vacuum deposition apparatus.

Since PC and tablet manufacturers continually increase the size of their screens, we have adapted to them. For that reason, we have invented new spray coating technology for applications.

In conclusion, this technology is part of our “Fussode COAT ™” series.

You can send your prototype to our coating technology development center. Your prototype will be given an evaluation test. Therefore, we require a contract and fee.