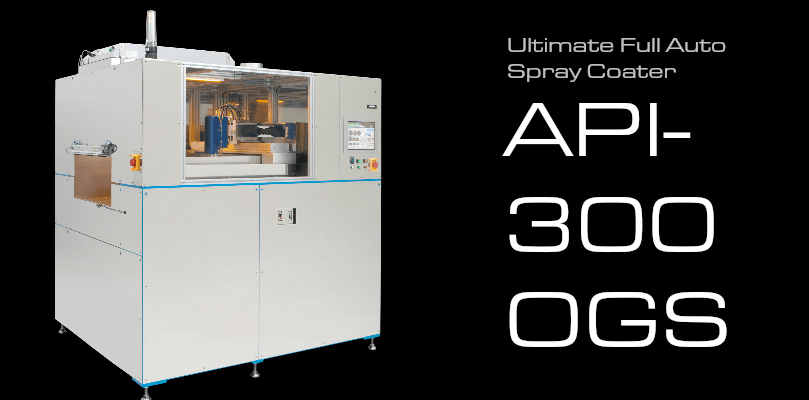

Apeiros API-300 Spray Coater

Apeiros API-300, a fully automated spray coater is a big favorite. Namely, the cover glass-integrated touch panel known as OGS. Therefore, ONE GLASS SOLUTION is the next-generation touch panel. To summarize, the definitive edition of the mass-production thin film spray coater! In addition, it corresponds to the various wet coating of the (OLED), organic EL. In conclusion, the API-300 is a mass-production spray coater with a maximum coating size of 550 x 650 (mm). Altogether, it is a fully automatic coating system that transports substrates with robots and conveyors. For example, by connecting to the front and rear devices on the line with data communications, you avoid trouble during downtime (cleaning timer setting, etc.). Consequently, the hardware and software assume all situations. Thus, equipped to contribute to the stable continuous production for our customers.

The Apeiros API-300 Spray Coater – external view

One case of OGS spray coater, for OC1 / OC2

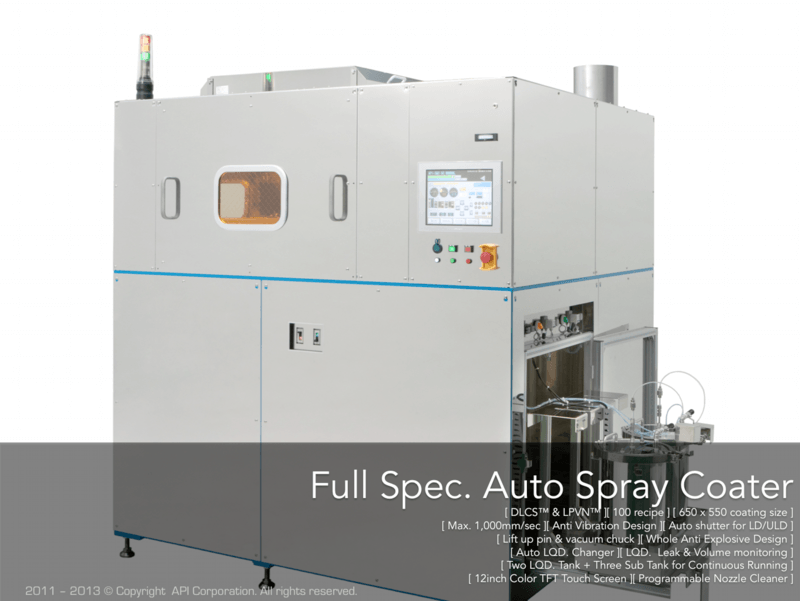

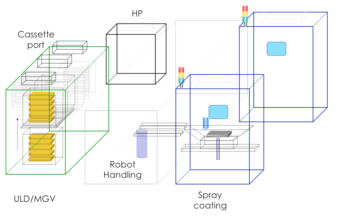

Perfect explosion-proof, various control functions suitable for continuous production. To include, robot, HP, by the integration of a cassette station, etc. Overall, you can build a fully automated line.

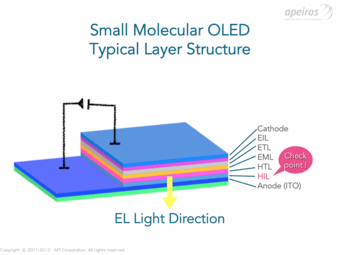

AMOLED buffer layer coating

Of low-molecular organic EL layer structure

ITO is coated with a buffer layer between (transparent conductive film) and HIL (hole injection layer)

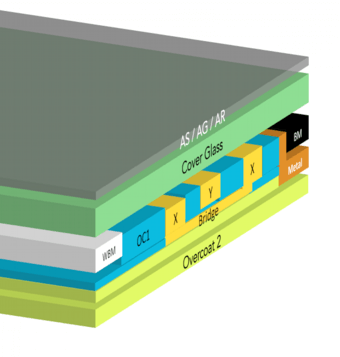

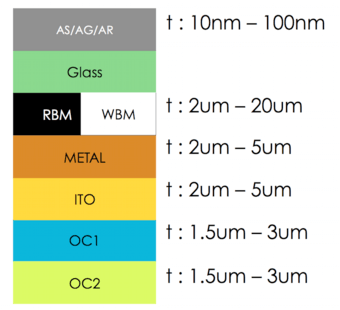

OGS layer structure

In Summary, all the functional thin film (AG / AR / AS) and a touch sensor of the photoresist film on the surface will respond with a spray coater.

In short, the functional film is an ultra-thin film of about 10nm-100nm. The layer structure of about 2um-20um in the resist film.

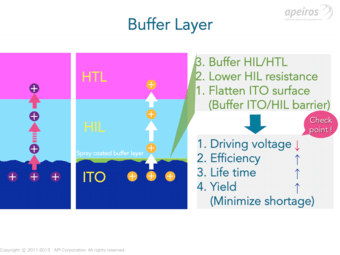

AMOLED buffer layer coating

Important to realize, the effect of the buffer coating.

Because the buffer coat may be to planarize the ITO film surface. Thus, enabling lowering the resistance value of the HIL layer, the driving voltage, or luminous efficiency. Therefore, has the effect of improving lifetime and yield.

API-300/400 full auto meters line

Spray coater fully automatic line

Therefore, it can be fully integrated with a robot, cassette port, and it is possible to be a hot plate. Finally, you can cross the mass production line. In fact, it can be customized with CIM communications.

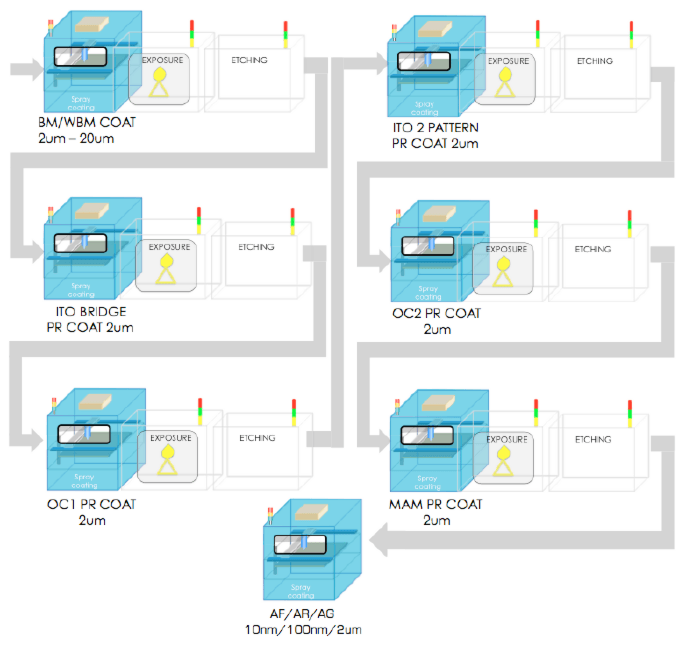

OGS deposition process

Apeiros API-300 High Precision Spray Coater

Must be remembered, the equipment specification!

| API-300OGS | API-420OGS | |

| Use | Identically, Photoresist coating of cover glass-integrated touch panel (OGS) (Black Matrix / ITO (X / Y) / MAM (Metal wiring) / OC1 / OC2) | |

| Equipment dimensions | 1,700 x 1,700 x 1,900 (WXLXH, mm) |

1,700 x 2,000 x 1,900 (W x L x H, mm) |

| Substrate size (= active application range) |

650 x 550 (mm) | 720 x 610 (mm) |

| Head speed | 1,000 mm / sec | |

| Height adjustment | 20mm – 100mm | |

| Board fixing method | Passing in the lift-up pin (robot), vacuum suction (lift the pin and the stage) | |

| Operation screen | 12 inches color TFT resistive touch panel | |

| Chemical supply system | Our own DLCS ™ system | |

| Liquid chemical relationship | the coating liquid tank capacity is 5L. The cleaning solution tank capacity is 5L. Markedly, the sub-tank (one each coating solution/cleaning solution and one for waste liquid) | |

| Recipe | Hundred | |

| Other standard features | Automatic chemicals supply. While featuring an automatic cleaning and degassing feature. automatic shutter when anti-sticking · · wait DATA log -thermo-hygrometer, atomization pressure monitoring nozzle clogging monitoring and exhaust differential pressure gauge · LED Light |

|

BACK TO MAIN Aperios Page click here!