Thermal print heads (TPH) are roughly classified into thick-film and thin-film types based on the manufacturing method, materials, and structure.

Printing Methods Using Thermal Printheads

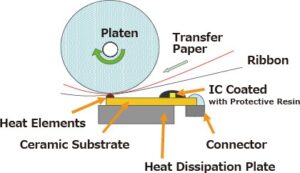

Thermal Transfer Method

Therefore, a wax or resin-based ink tape (ribbon) is melted (glued) onto a material such as paper using heat.

Advantages |

|

|---|---|

Disadvantages |

|

Thermal Method

Therefore, printing is achieved by contacting heat elements with thermal paper (special heat-sensitive paper). Frequently used for receipt printers.

Advantages |

|

|---|---|

Disadvantages |

|