What is Deburring?

To point out, we have Deburring Machines.

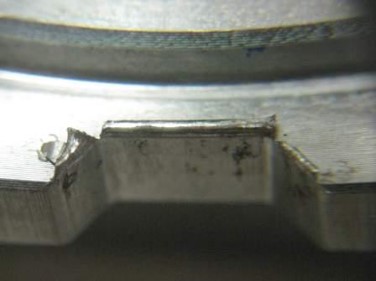

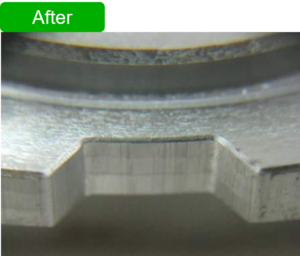

All metal manufacturing processes produce burrs or sharp uneven edges along the surfaces. Deburring machines remove the burrs. Therefore, to deburr parts, a manual process is often required. These burrs can be tedious and time-consuming to remove. Consequently, affecting the overall quality of the workpiece.

In fact, Texmac Machine Tools provides two solutions. Ultimately, our machines will automate the deburring process. Overall, improve consistency and productivity.

Water Jet Deburring

The FE-Movac CNC Water Jet deburring Machine uses 7000 psi water. Consistently removes difficult burrs with precision and accuracy.

For this reason, parts leave the machine free of any oil or coolant. Due to the machining process.

Ready to discover more?

See why the FE-Movac Deburring Machine is the right solution to automate your deburring process.

Click Here To learn more about FE-MOVAC Deburring!

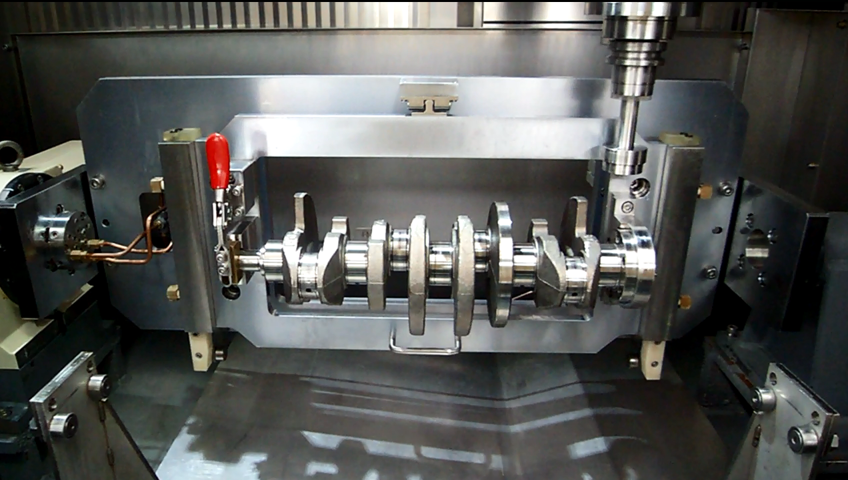

Profile Deburring

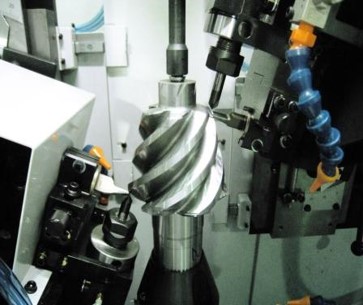

As a result. chamfering and Deburring are no longer an afterthought. Introducing the SENJO SEIKI automatic deburring and chamfering machines. Surely, manufacturers can now quickly and uniformly complete gear and part chamfering. So as to the exact specifications with no programming.

Machine Features

Chamfering and Deburring Features

In the first place, programming and positioning are not required.

Furthermore, SENJO SEIKI machines incorporate a patented stylus tracing unit. Therefore, it eliminates the need for component placement or computer programming. Which are needed in CNC machinery.

Chamfering Accuracy

To point out, the stylus traces the inner or outer periphery of a machined component. Thus, guiding the cutter axis to create a uniform and symmetrical chamfer. Therefore, it requires no further finishing and is highly consistent from part to part.

Eliminate Large Burrs

In fact, large burrs can be eliminated from their base in only one step.

User-Friendly Operation

To point out, that the machined component positioning is not required. The control wheel and knob easily adjust the chamfering size and rotational speed.