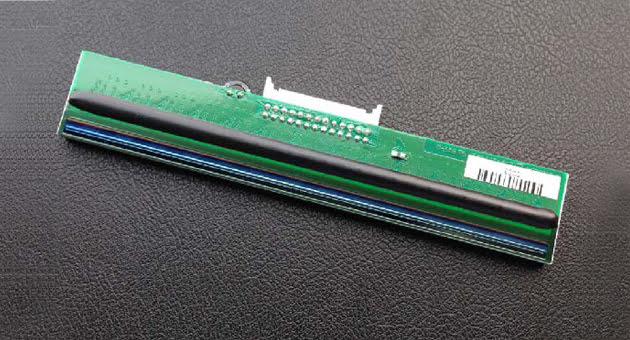

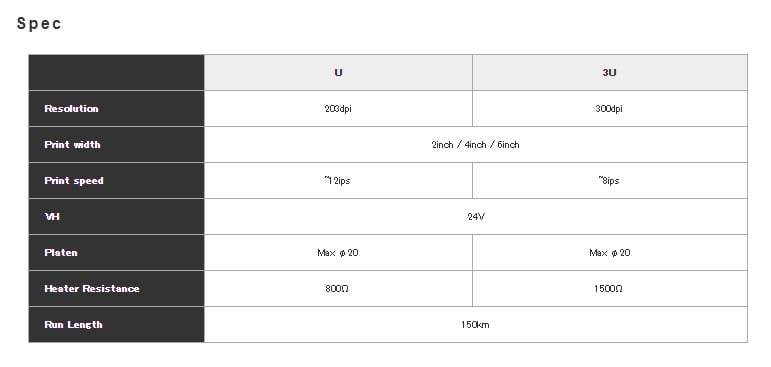

TPH for Barcode Label Printers (Thin Film)

Thermal Print Heads for Barcode Label Printers (Thin Film)

TPH for Barcode Label Printer labels is printed using either thermal transfer or direct thermal printing technology. So, let’s talk about what they have in common. Similarly, thermal transfer and direct thermal use heat as the activator to transfer an image onto the label. The heat is generated from a printhead inside the printer. In other words, it heats up when a label is passed over it to “print” the image on a label.

So, how do they differ? The thermal transfer printer uses a ribbon as the mechanism for imaging the label. The thermal transfer ribbon, with a special black coating on one side, is wound on a roll. Since this coating is usually made from a wax or resin formulation.

During thermal transfer printing, the ribbon is run between the label and the printhead. The ribbon and label will pass over the printhead. Therefore, the printhead heats up the ribbon’s coating causing it to transfer from the ribbon to the label. Therefore, the printing on that label came from the coating that was on the thermal transfer ribbon.

In fact, the primary reasons for choosing thermal transfer printing are print quality, durability, and label longevity. Thermal transfer ribbons come in a variety of formulations. For instance, simple everyday printing to harsh environments. The printed labels are able to withstand exposure to chemicals and solvents. Above all, thermal transfer labels will last longer and withstand moisture, abrasion, and exposure to UV better than direct thermal labels.