Over 50 years, TMT accumulated experience and knowledge in synthetic fiber production. Specifically, FDY Spinning Machines are part of the Spinning System, developed with total engineering expertise and knowledge. Therefore. enables the configuration of the optimum system to fit various conditions of spinning for materials. For Example, PET, PA, microfilaments, dope-dyed yarn, high-modulus low-shrinkage yarn (HMLS/LS), to new materials such as PTT, PLA, and so forth.

FDY Spinning Machines Features:

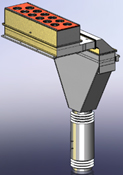

SPINNING BEAM

Energy-saving & Space-saving design. Other than the conventional 1 thread line per pack, there is an option to use the 2 thread lines per pack to save space.

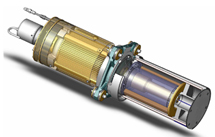

QUENCH CHAMBER

You have the selection of the quench chamber suitable for producing various yarn types. Other than the conventional cross-flow, the iQC can achieve high quality & energy saving, maximum up to 576 filaments.

TAKE-UP FRAME

TMT can provide various roller layout having experience world wide. TMT’s 300-500mm in-house heated rollers with an exclusive heating method will maintain even surface temperature.

Winder

You will have the selection of the ATi-series, Manta series according to your yarn type demands. High efficiency with a maximum of 32 thread lines.