Digital Liquid Control System ™ DLCS ™

In pursuit of the ideal spray coating technology!

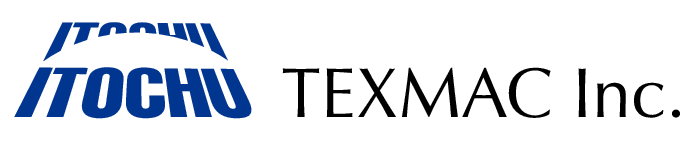

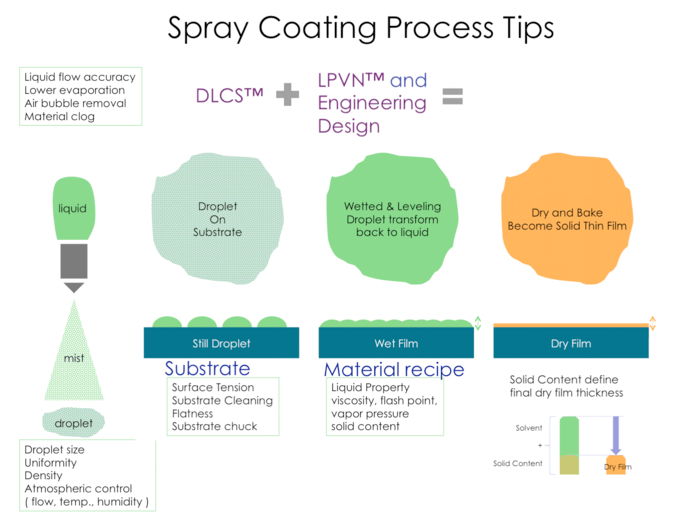

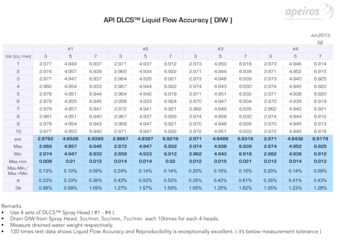

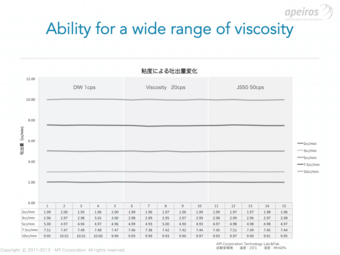

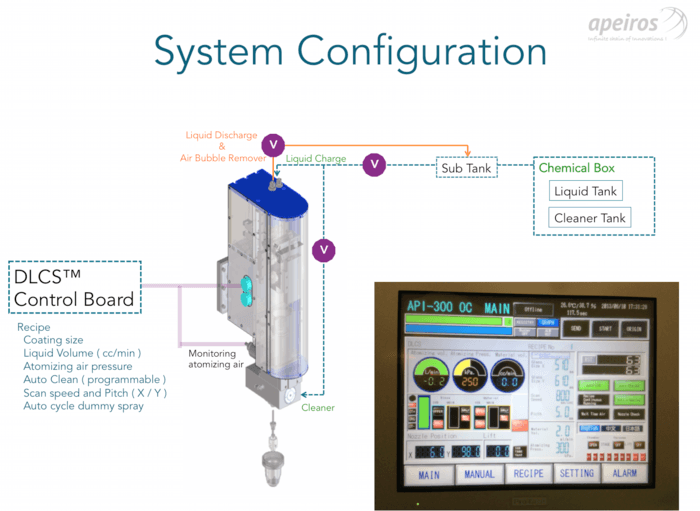

Digital Liquid Control System, DLCS ™ is a monolithic spray head that achieves a discharge accuracy of 0.1-1.0%. Included are a two-fluid nozzle, sub-tank, degassing mechanism, and filter. Specifically, to enable stable discharge without pulsation. Consequently, conventional flow control technology and our own flow control scheme achieve the ultimate discharge accuracy.

Spray head with a built-in DLCS ™, clog monitoring, automatic degassing, automatic cleaning. Additionally, a filter (optional) function, chemical tank (40cc / 60cc), and monolithic spray head. A built-in proprietary low-pressure atomization nozzle (LPVN ™) has become the structure. In conclusion, our engineering design gives you a uniform high-quality spray coating.

To include:

For one thing, Liquid flow accuracy.

Lower evaporation

In fact, air bubble removal

Mitigation of material clogs

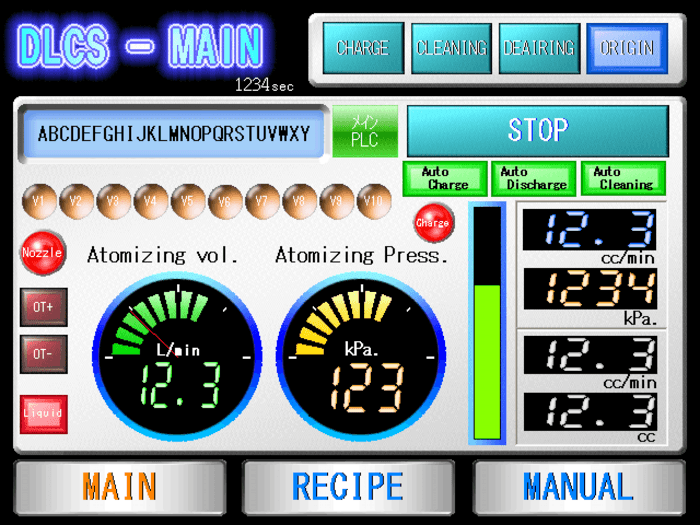

Apeiros utilizes spray coating control technology based on many years of spray coating experience. The system’s 12” touch panel allows for control of all system functions. For instance, application parameter setting, nozzle cleaning, air bubble removal, recoating, and application status monitoring system. In addition, you can record temperature, humidity, application conditions, and equipment status during operation. This can be saved as log data to provide feedback during mass production control.