AMADA Stamping Press

AMADA Stamping Press machines are used to produce a large variety of metal parts.

The Stamping Press machines are used in the following industries:

- Automotive

- Washers & Dryers (Whitegoods)

- Electrical & Electronic Components (IE – Motor Laminations, Wire Connecting Terminals, Computer Chassis, & Lead-frames)

- Motorcycles

- Trucks

- HVAC

- Commercial Shelving

- Metal Containers

- Flatware

- Etc.

Model Size ranges from 15 Ton C-Frame to 400 ton Straight-Side Presses.

AMADA Stamping Press Machines

Digital Electric Servo:

Digital Electric Servo presses are crank, link, knuckle, multistep, pendulum, and pulse motion. Additionally, you can set the slide motions and strokes for specific applications. Therefore, better productivity than that of conventional stamping press product systems.

Digital Electric Two-Point Servo Presses:

The digital servo direct drive provides for two-point stamping. The digital servo direct drive is used for precise slide motion. Additionally, when combined with a highly rigid one-piece side frame. Therefore, high stability, accuracy, and productivity are accomplished.

Double Crank Presses:

Double Crank Presses use an installed planetary gear transmission. Additionally, to ensure stable and continuous stamping we use a wide bed. A TFT color touch screen is a standard item and provides better visibility and operability. In addition, Eco-functions reduce power consumption.

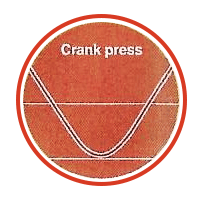

Single Crank Presses:

The Single Crank TP-FX Press series adopts a highly rigid frame. It has a six-sided guide of construction designed to prevent eccentric loading. Therefore, the Single Crank TP-FX Press is a long-selling press focusing on stamping accuracy and versatility.

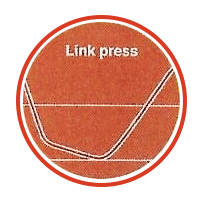

Double Link Presses:

The Double Link C-frame two-point presses come standard with link mechanisms. Thus, we bridged the Double Link Presses with BI, BO, BN, and SF types. Therefore, limiting the gap opening in pursuit of higher stamping accuracy. Additionally, the Eco-functions reduce power consumption.

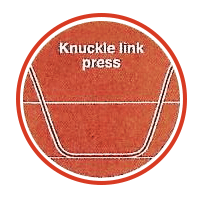

Knuckle Link Presses:

The Knuckle Link presses are extremely accurate presses. The knuckle mechanism will slow down near the bottom dead center, and it will practically stop at the bottom dead center. This will ensure accurate plastic working. In addition, the slow return improves machine availability.

The highly rigid frame and bed structure are several times higher than that of conventional presses. The frame and bed structure, combined with an optimum highly rigid structure of column, slide, and crown. The total elongation is 0.005 mm/10 kN or less.

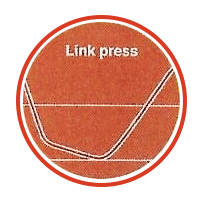

Single Link Presses:

The Single Link Presses deliver unprecedented productivity. Thus, producing higher than average accuracy, and deep formability. Therefore, Eco-functions reduce power consumption. In conclusion, the operability and machine data management are optimized.

To learn more about Amada click here.